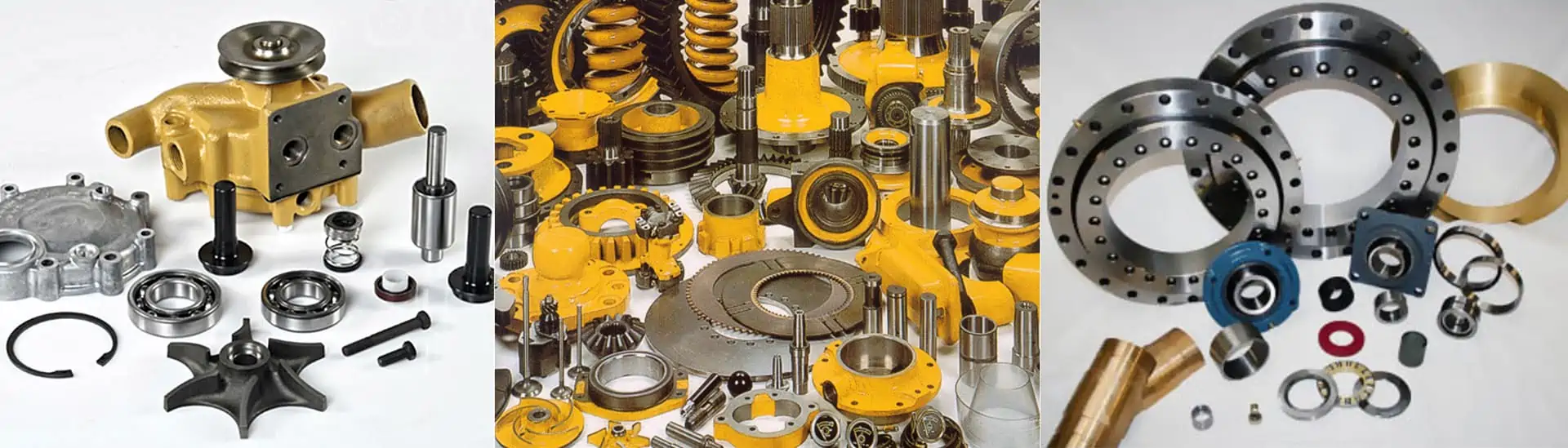

Enhance Your Hefty Machinery With Top Quality Aftermarket Building Components

Enhancing heavy machinery with high quality aftermarket building components can dramatically impact the efficiency and long life of your tools. From increased productivity to affordable services, aftermarket building parts provide a variety of advantages that provide to the varied demands of hefty equipment drivers.

Advantages of Aftermarket Building Components

Enhancing heavy machinery with aftermarket building and construction components can dramatically improve efficiency and long life. Among the crucial advantages of making use of aftermarket building and construction parts is the capacity for improved sturdiness. Aftermarket parts are frequently developed with upgraded products and modern technologies, which can result in machinery that can hold up against extra extensive operating conditions. This increased durability can bring about minimized downtime for maintenance and repair work, ultimately boosting general efficiency and performance.

Furthermore, aftermarket building parts can use cost financial savings compared to acquiring initial equipment maker (OEM) parts. While OEM components are typically a lot more expensive because of brand name recognition and exclusivity, aftermarket alternatives provide a more economical option without endangering on quality. This cost-effectiveness can be specifically beneficial for firms looking to enhance their functional costs without giving up the efficiency of their heavy machinery.

Variables to Think About When Choosing Parts

When selecting building and construction parts for heavy equipment, it is crucial to thoroughly take into consideration different factors to make sure optimum efficiency and compatibility. One essential variable to take into consideration is the quality of the components. Choosing premium aftermarket building and construction components can significantly influence the overall efficiency and long life of the equipment. It is necessary to select parts from trustworthy producers known for their sturdy and dependable items.

Another element to take into consideration is compatibility. Making sure that the construction components work with the particular make and model of the machinery is vital to avoid any functional concerns or damage. This includes verifying the dimensions, specs, and any type of extra requirements for seamless integration.

Furthermore, taking into consideration the cost-effectiveness of the parts is vital. While top quality needs to not be jeopardized, choosing aftermarket parts that supply an excellent balance between high quality and cost can aid in optimizing the worth of the financial investment.

Finally, availability and consumer support should additionally be considered. Select building parts that are easily available and backed by superb client support to attend to any questions or concerns without delay. By thoroughly assessing these variables, you can make educated decisions when picking aftermarket construction components for your hefty machinery.

Setup Tips for Aftermarket Parts

To guarantee a smooth and reliable installation process for aftermarket construction components on heavy machinery, thorough focus to detail and adherence to maker standards are vital. Prior to starting the setup, it is important to extensively check the aftermarket components to validate that they match the specifications of the original parts and are cost-free from any kind of flaws. In addition, arranging the workplace and making certain that the essential tools are readily offered can help simplify the setup procedure.

Following the supplier's setup instructions is necessary to assure appropriate fit and functionality of the aftermarket components. Any kind of variance from these guidelines could lead to subpar efficiency or even possible security hazards. It is likewise a good idea to document the installation procedure, consisting of any kind of adjustments made or obstacles experienced, for future referral.

Finally, performing click this link a final evaluation after the setup is total can assist determine any problems or mistakes that may have been forgotten - aftermarket construction parts. Evaluating the machinery to make certain that the aftermarket parts are functioning appropriately is a vital final action in the installment process

Maintenance Standards for Upgraded Machinery

For ideal performance and durability of upgraded machinery, adherence to particular upkeep standards is important. Regularly arranged upkeep checks are necessary to make sure that all aftermarket components are operating appropriately. This includes checking parts for wear and tear, lubing moving components, and changing filters as required. Following the producer's suggested upkeep routine is extremely suggested to stop unexpected break downs and expensive repair services.

In enhancement to routine maintenance, drivers ought to additionally focus on any unusual sounds, resonances, or efficiency issues that may emerge. Addressing these problems without delay can protect against more damages to the machinery and its aftermarket parts. Maintaining thorough records of upkeep tasks, repair services, and part replacements can aid track the general health of the upgraded equipment and determine any recurring problems.

In addition, correct storage and cleaning procedures should be complied with to secure the machinery from ecological elements that could increase wear on aftermarket components (aftermarket construction parts). By following these maintenance guidelines diligently, drivers can take full advantage of the advantages of their updated machinery and ensure its continued integrity at work site

Cost-efficient Upgrades for Heavy Equipment

Carrying out tactical upgrades can dramatically enhance the performance and performance of heavy equipment while maintaining cost-effectiveness. When thinking about cost-effective upgrades for heavy machinery, it is crucial to prioritize enhancements that provide one of the most significant effect on productivity without breaking the spending plan. One affordable upgrade is the setup of advanced telematics systems. These systems give real-time data on equipment use, fuel usage, and upkeep needs, enabling for aggressive decision-making and decreasing downtime.

Updating to even more resilient tires or tracks can have a peek at these guys additionally be a wise financial investment, as they can improve traction, reduce wear and tear, and inevitably prolong go the life expectancy of the equipment. By carefully picking and carrying out these affordable upgrades, heavy machinery operators can make best use of efficiency and efficiency while remaining within budget plan constraints.

Verdict

In verdict, aftermarket construction parts supply countless benefits for boosting heavy equipment. By very carefully considering variables such as compatibility and high quality, choosing the ideal components can enhance performance and prolong the lifespan of devices. Proper setup and normal maintenance are essential for making sure optimal capability. Generally, cost-effective upgrades with aftermarket components can bring about enhanced performance and productivity in building procedures.

Enhancing heavy equipment with high quality aftermarket construction components can considerably affect the efficiency and longevity of your devices.Enhancing heavy equipment with aftermarket building parts can substantially boost efficiency and long life.In addition, aftermarket construction parts can provide price savings contrasted to acquiring original devices maker (OEM) components.To make sure a reliable and smooth installment process for aftermarket building parts on heavy equipment, meticulous attention to detail and adherence to manufacturer standards are paramount. Prior to starting the installment, it is vital to thoroughly inspect the aftermarket components to validate that they match the specifications of the initial parts and are free from any defects.